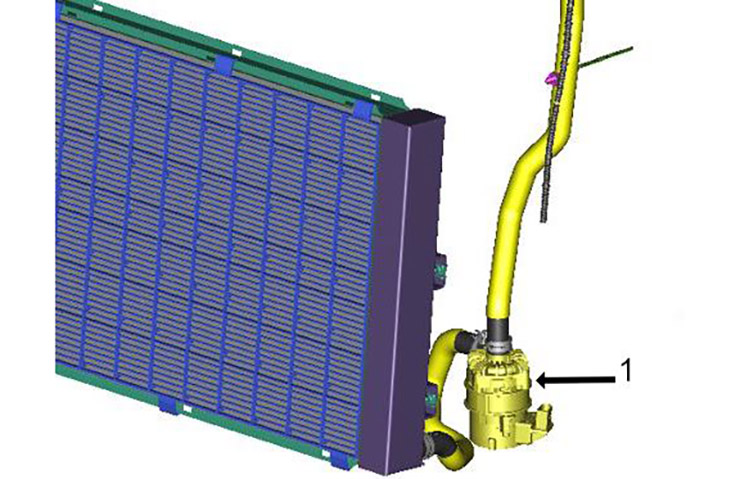

The all-new Duramax®柴油3.0L内联6缸涡轮增压发动机(RPO LM2)提供了大量的功率 - 生产282马力和450磅。速率。扭矩 - 随着令人印象深刻的燃油经济性 - 在一个有效的包装中估计了估计的30 mpg(7.8L / 100km)高速公路 - 在一个有效的包装中。(图1)在2020 Silverado 1500和Sierra 1500型号上提供,它配对10L80 10速自动变速箱(RPO MQB)。

Fig. 1

Fig. 1

Turbocharged Performance

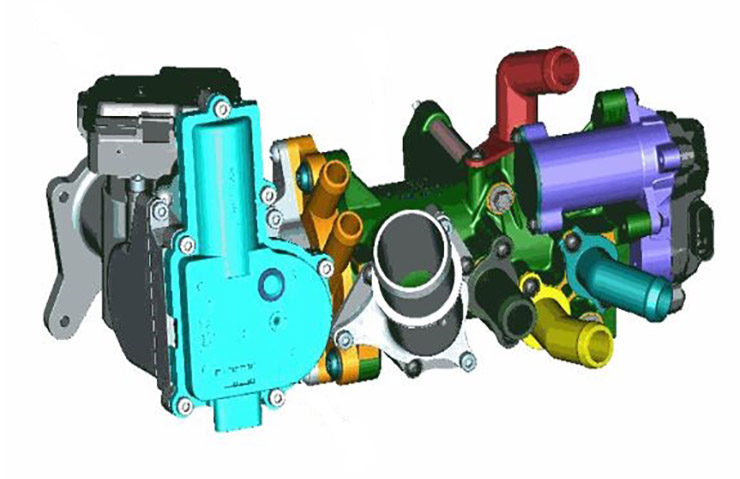

The dual overhead camshaft (DOHC) engine uses an aluminum block with six pressed-in iron sleeves and a high pressure diesel fuel injection system. The lower oil pan is made of dual-layer stamped aluminum. (Fig. 2)

The 3.0L diesel engine uses SAE 0W-20 dexosD diesel engine oil. Do not add anything to the oil.

Fig. 2

Fig. 2

The turbocharger is a variable nozzle design with an electric vane actuator attached to the exhaust manifold. The Variable Geometry Turbine (VGT) body assembly contains a contact-less inductive VGT position sensing element that is managed by a customized integrated circuit. The VGT position sensor provides a signal voltage that changes relative to the VGT vanes angle. The customized integrated circuit translates the voltage based position information into serial data using Single Edge Nibble Transmission (SENT) protocol. The VGT position sensor information is transmitted between the VGT body and the Engine Control Module (ECM) on the signal/serial data circuit. The ECM decodes the serial data signal and is used as voltages for the VGT position sensor.

The intake manifold houses the integrated intercooler. The intercooler system includes an air cooler/heat exchanger built into the intake, a charge air cooler (CAC) radiator assembled in the front fascia, and an electric coolant pump. The CAC coolant pump provides operational and diagnostic feedback to the ECM. (Fig. 3)

Fig. 3

Fig. 3

The fuel system features a 3-phase electric fuel pump in the fuel tank that is controlled by the fuel pump driver control module and the ECM. Fuel is pumped from the fuel tank to the fuel filter assembly, which consists of a fuel filter/water separator, fuel heater, fuel temperature sensor, and a water in fuel sensor.

The ECM controls the fuel injection timing and has the ability to learn injector timing performance. Under the correct operating conditions, the ECM will pulse each injector individually and measure the changes in rotational speed of the crankshaft using the input from the crankshaft position sensor. The ECM will run this diagnostic at one fuel rail pressure operating point for each injector. The ECM stores the injector timing value.

主动热管理

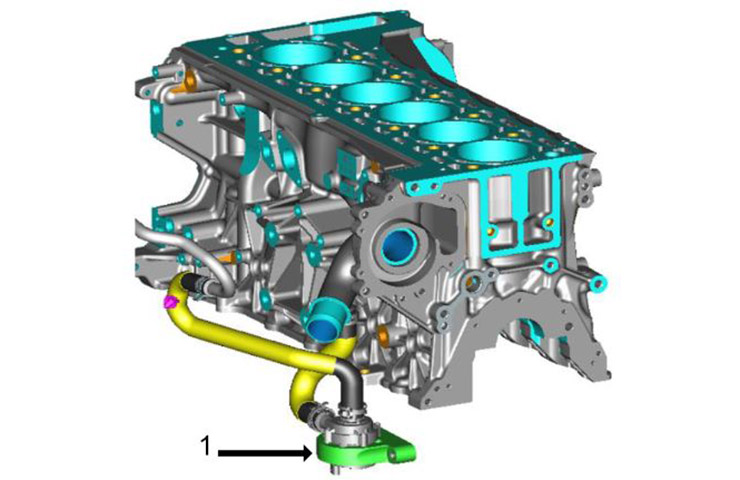

The Active Thermal Management (ATM) system on the 3.0L diesel engine distributes coolant through the engine in a targeted manner, sending heat where it’s needed to warm up the engine and reduce friction. It also promotes quicker heating of the passenger compartment and enhanced engine cooling during high power operation. The system uses a conventional engine-driven coolant pump while the ECM controls the ATM system using feedback from various coolant temperature sensors.

The engine coolant flow control valve assembly that is part of the ATM system uses two chambers to control coolant flow. (Fig. 4) The first chamber controls the coolant flow rate across the radiator and bypass. The second chamber controls the flow to the transmission and engine oil cooler as needed, providing heated coolant from the EGR/turbocharger return circuit or cold coolant directly from the pump outlet.

Fig. 4

Fig. 4

Exhaust Aftertreatment System

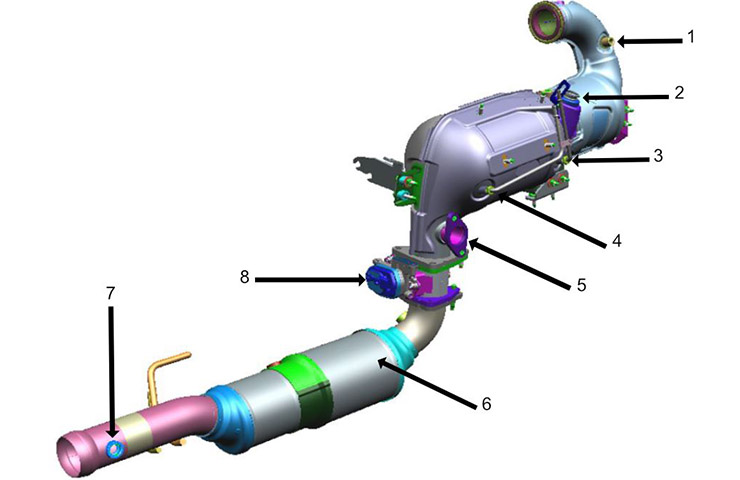

排气后处理系统的目的是reduce the levels of hydrocarbons (HC), carbon monoxide (CO), oxides of nitrogen (NOx), and particulate matter (PM) pollutants remaining in the engine’s exhaust gases before they exit via the vehicle’s exhaust tailpipe. NOx is controlled by a Selective Catalytic Reduction (SCR) converter combined with precise injections of Diesel Exhaust Fluid (DEF), while PM is controlled by a diesel particulate filter (DPF). To reduce packaging volume and manufacturing cost, the SCR catalyst on the DPF is coated to form an SCR-coated DPF, or a Selective Catalytic Reduction on Filter (SCRoF). The close coupled DOC along with the SCR on Filter are integrated into one assembly.

In the DPF, particulate matter consisting of extremely small particles of carbon remaining after combustion are removed from the exhaust gas by the large surface area of the DPF. DEF is injected into the exhaust gases prior to entering the SCRoF stage. Within the SCRoF, NOx is converted to nitrogen (N2), carbon dioxide (CO2), and water vapor (H20) through a catalytic reduction fueled by the injected DEF.

排气后处理系统组件(图5)包括:

- Exhaust temperature sensor

- DEF注射器安装法兰

- Exhaust pressure differential sensor pipe

- Exhaust pressure differential sensor pipe

- EGR flange

- NOx catalytic converter assembly

- Particulate matter boss

- Exhaust back pressure valve

Fig. 5

Fig. 5

由蓝色盖子识别的DEF填充位于燃料填充门后面。(图6)在填充DEF罐之后,除非DEF罐是空的,在检测到增加的流体水平之前可能存在短延迟并且更新驾驶员信息中心上所示的DEF水平。

Fig. 6

Fig. 6

Automatic Engine Stop/Start System

Designed to help conserve fuel, the Automatic Engine Stop/Start system may turn off the engine when the brakes are applied and the vehicle is at a complete stop, if the required operating conditions are met. The tachometer will read Auto Stop.

The Stop/Start system can be disabled and enabled by pressing the Stop/Start switch on the center of the instrument panel. (Fig. 07) The system is enabled each time the vehicle is started.

Fig. 7

Fig. 7

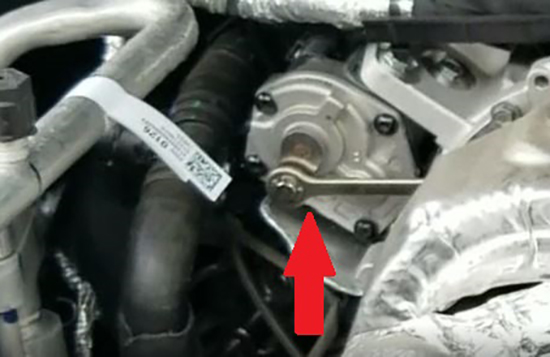

An auxiliary electric engine coolant pump motor (Fig. 8) continually circulates engine coolant through the heater core while the Stop/Start system has shut down the engine and the ambient temperature is colder than 59°F (15°C) to maintain the passenger compartment temperature.

Fig. 8

Fig. 8

The 3.0L diesel engine also features an active engine mount system to enable an optimal balance between vehicle Noise Vibration and Harshness (NVH) performance and vehicle dynamics, including during Automatic Engine Stop/Start events. There is a single solenoid on each active engine mount that is energized during an ignition event and switched on for idle and driving events. The solenoid valves are supplied with battery voltage through a single fuse and are controlled by the ECM.

Normal Sounds After Engine Shut-Off

After the 3.0L diesel engine has been shut off, several sounds may be heard in the engine bay. These sounds may be caused by the following components performing a cleaning cycle:

- Turbocharger linkage (Fig. 9)

- 排气节流阀

- Intake manifold swirl valve

Fig. 9

Fig. 9

The sounds are normal operating characteristics of the vehicle and do not impact the designed performance or reliability of the vehicle.

Refer to Bulletin 19-NA-188 for additional information.

Special Tools

The following new tools were released for the 3.0L diesel engine:

| Tool Number | Description |

| EN-52445 | Camshaft Tool |

| EN-52446 | Rear Crankshaft Seal Installer |

| EN-52448 | High Pressure Fuel Pump Tool |

| EN-52449 | Engine Stand Adapter |

| EN-52451 | Fuel Injector Remover |

| EN-52452 | Installer, Front Crankshaft Seal |

| EN-52474 | 发动机升降支架组件 |

| EN-52579 | Crankshaft Rotator Tool |

| EN-52586. | Fixing Pin, Crankshaft Timing |

| EN-50717-20 | Valve Spring Compressor Adapter |

有关新的3.0L DURAMAX柴油发动机的更多详细信息,请参阅公告#19-NA-180。

– Thanks to Javier Hinojos and Sherman Dixon

据我所知,中间冷却器是一个单独的

系统。有两个冷却水库,我相信它有一个专用泵。

Does the intercooler system share coolant with the engine or are the two systems completely isolated?